· Ioana Cozmuta, Remus Osan, Brian Motil · Papers · 2 min read

G-SPACE: An AI/ML Microgravity DOE Platform to Enable Profitable In Space Manufacturing

There is a big gap between current microgravity R&D and the emerging field of in-space manufacturing.

Abstract

There is a big gap between current microgravity R&D and the emerging field of in-space manufacturing. Addressing this gap will require improvements in microgravity product development since products manufactured in microgravity need to meet both performance (uniqueness or superiority) and economic requirements.

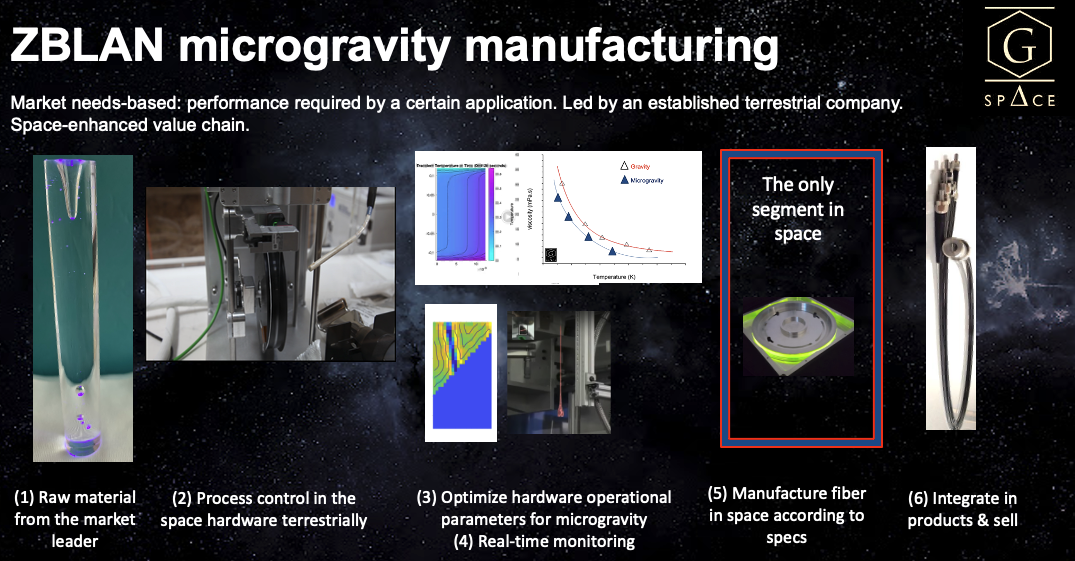

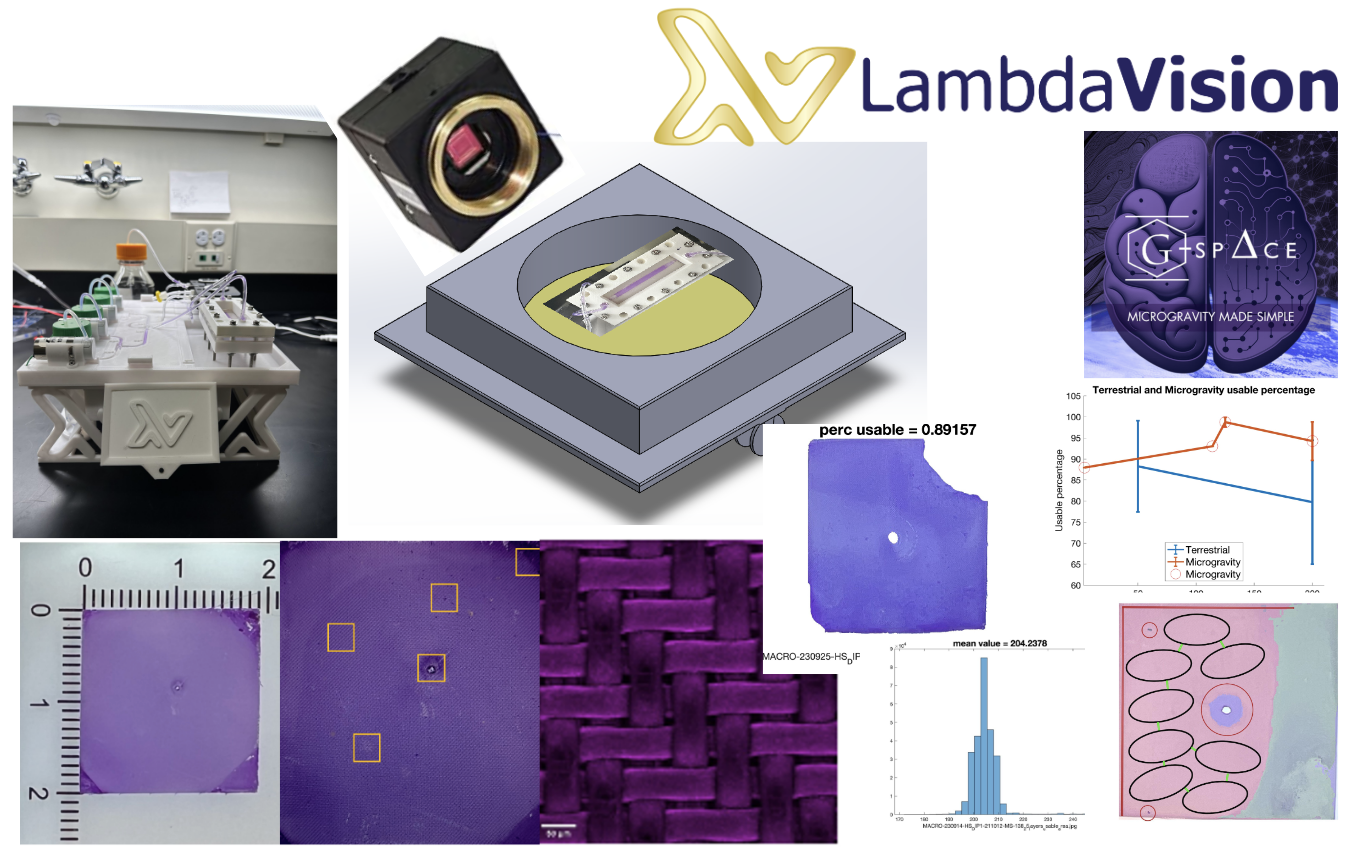

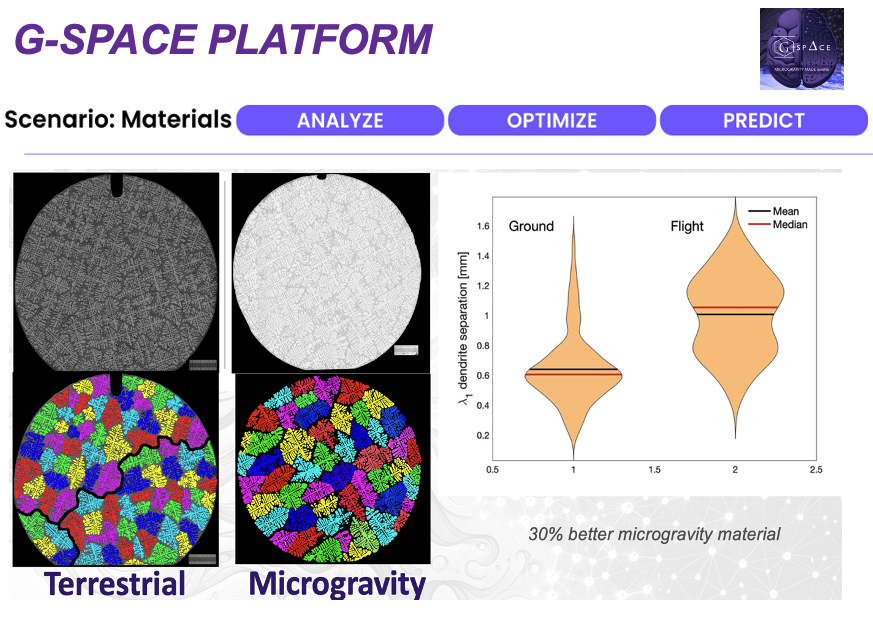

G-SPACE’s AI/ML-powered software platform is introduced as an innovative solution, designed to efficiently transform microgravity R&D into commercially viable products. This platform leverages proprietary Computer Vision (CV) and Machine Learning (ML) algorithms to identify key physical properties unique to microgravity environments, systematically linking these properties to product performance.

With over 150 proof-of-concept projects under its belt, G-SPACE tackles key obstacles in space exploration:

- The underestimated impact of gravity;

- A lack of standardized tools to design, test, and analyze microgravity experiments;

- Low in-space manufacturing yields

- Significant risks to data and process control.

The platform offers a comprehensive solution for the rapid response monitoring, analysis, and control of microgravity operations, paving the way for more efficient and safer space activities. It enhances the safety of payloads and optimizes the return on investment in space innovation, ensuring better outcomes.

For instance, G-SPACE’s platform allows microgravity Principal Investigators (PIs) to rely on standardized, modern analytic tools for expanded data interpretation, to bring investigations to a clearer conclusion and elevating science and translational readiness. It facilitates systematic tracking across multiple studies, enhancing cyclical learning.

This presentation will highlight G-SPACE’s analytical capabilities across various microgravity investigations, including studies on semiconductor materials, biological tissues, printed electronics, plants, optical fiber and beyond. As we accumulate more data, the predictive power of our ML-models will further improve, enabling the development of advanced models that capture the Delta-to-GravityTM for predicting new material properties and performance enhancements. This predictive capability is crucial for meeting the needs of industrial applications in space.

G-SPACE’s unique digital platform is set to revolutionize the way data from microgravity is utilized, promoting standardization, enhancing process control, reducing costs, and expediting the commercialization of microgravity products. This innovative approach not only propels the field of in-space manufacturing forward but also aligns with the evolving economic and performance requirements of space-based products.